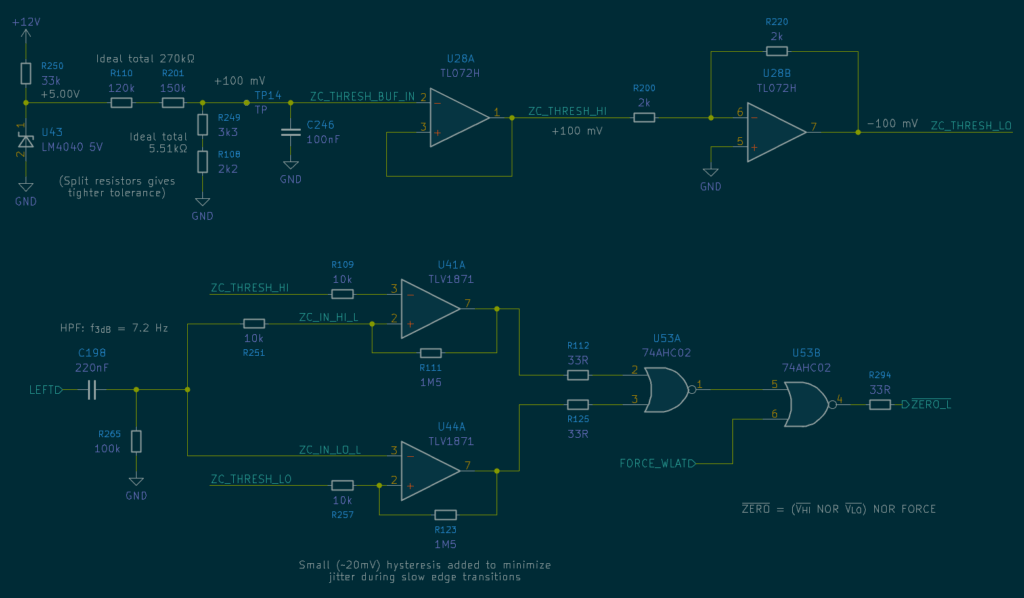

I need a minimal-lag zero-cross detector for the tone control section of an audio preamp which will rely on digital potentiometers for adjustment. The pot adjustments (communicated from an MCU over SPI) need to be sync’d to 0V input to avoid popcorn noise.

The digital pot has a write-inhibit input that can be driven low to latch the adjustment while the input signal is crossing 0V. My goal is to hit this pretty close to the mark (±100mV), for any audio-rate signal, which may be up to 3.5 Vrms (~10 Vpp) and 20 kHz. To be valid, the signal needs to remain low for 25ns. I’d like to hit this with room to spare and also minimize signal bounce / glitching for a slowly-changing audio-rate input.

A new IC by Texas Instruments that makes this possible with high resolution and minimal phase lag is the TLV1871.